Aluminum Sheet (Series 5)

- Commodity name: Aluminum Sheet (Series 5)

KEYWORDS:

Aluminum Sheet

B

- Product Parameters

- Product Advantages

- Applications

-

>>>>>> 5××× Series Aluminum Sheet

This aluminum-magnesium alloy sheet (Al-Mg) uses magnesium as the primary alloying element. It offers excellent formability, corrosion resistance, and weldability. It is widely used in conventional industries due to its low density and lighter weight than other aluminum sheet series. It is also commonly used in ship structures, aircraft fuel tanks, and automobile fuel tanks. Currently, 5052 and other series aluminum sheet are commonly used in the architectural and decoration industries.

-

- Extremely Corrosion-Resistant: Magnesium optimizes its corrosion-resistant structure, making it particularly resistant to seawater, humid, and chemical environments. It can be used outdoors, in the ocean, or in mildly corrosive environments without requiring complex processing.

- Balance of strength and plasticity: The strength is higher than that of Series 1 and Series 3, and the plasticity is good. It can be strengthened by cold working and can withstand bending, stamping, and welding. It is suitable for making structural parts that are subjected to stress and need to be formed.

- Lightweight adaptation: low density, light weight, and excellent strength-to-weight ratio. It can take into account both structural strength and weight reduction requirements in the fields of transportation (ships, vehicle components), marine engineering, etc.

Certificates

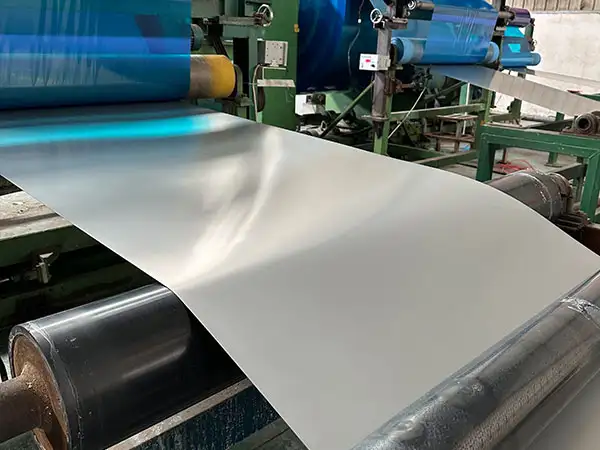

Factory Show

Demonstration Of Equipment Or Cases5

Orange Peel Aluminum Coil

Anodized aluminum coil

Demonstration Of Equipment Or Cases4

Demonstration Of Equipment Or Cases3

Demonstration Of Equipment Or Cases6

Demonstration Of Equipment Or Cases2

Demonstration Of Equipment Or Cases

Corporate Advantage

Meet Diverse Needs

The company has a wide range of products, including aluminum plates, oxygen oxidation, brushed printing, etc., which can meet the diverse needs of different customers and different industries.

R&D And Innovation Capabilities

A strong R&D team and continuous R&D investment enable the company to continuously launch new products and new technologies to meet market needs and customer personalized requirements.

Professional Talent Team

We will continue to introduce advanced production equipment and processes to meet the changing needs of our customers.

Strict Quality Control

The company has established a complete quality management system. From procurement, production and processing to product inspection, all links strictly control quality standards to ensure the high quality and stability of products and improve product reliability and service life.

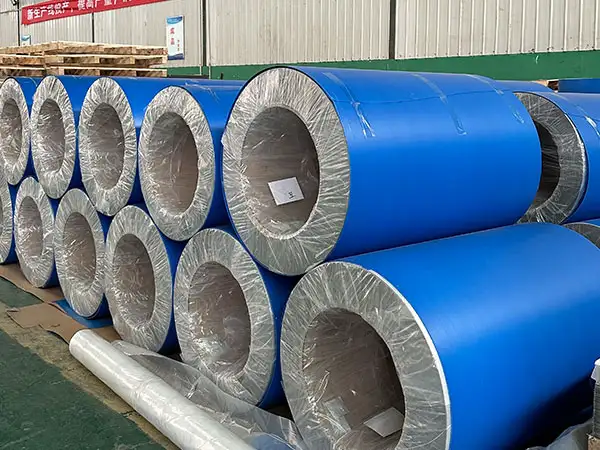

Transportation Packing

Customer Visits

FAQ

What payment methods do you support?

We basically support T/T,L/C and D/P. If you like to choose other payment methods, please consult us directly.

What are the opening hours?

Since we service customer worldwide, we accept your inquiry and questions 7*24 hours. When we receive your message or email, we will reply you in the first time.

I recently ordered some anodized material that does not match the same material with the same finish that I ordered previously. Why is that?

There are many variables that may lead to color inconsistencies in anodized finishes.

Any variation in alloy or temper of aluminum being finished can result in color variation. For example, an aluminum bar run at one mill may anodize differently than the same bar run at another mill due to only a very small difference in magnesium content.

In addition, length of time spent in the anodizing "bath" can affect the final color.

Our finishers are cognizant of these factors, and continually monitor their systems to maintain the best possible color consistency from batch-to-batch and order-to-order.

For a premium, it is possible to obtain material that all comes from the same "lot," which means it was all produced in the same run. This is one way to improve the odds of a consistent finish throughout all of the material.

What type of packaging options do you offer?

We can offer many custom packaging options, from standard square, rectangular, and round to full protective boxing, as well as eye-to-the side packing for wide width coils. We can custom design the package you want and meet your weight, height and handling needs.

What makes the price of aluminum change?

Aluminum is traded like all metals and subject to market price fluctuations based on supply, demand, and many other factors.

Why aren't standard price lists available for your products?

Costs of materials are subject to frequent changes due to fluctuations in the market, costs of raw materials, and other factors. These changes could affect selling prices.

Can you sell in cut sheets or strips?

Yes, minimum productions may apply. Please inquire.

Need help? We're here to help!

Please feel free to contact us and we will get back to you within an hour.

Related Products